- Show:

Showing all 20 results

What are Drip Trays?

Drip trays are the simplest form of containment devices that are made from several materials and are available in various shapes and sizes. It is a container that catches oil, liquids or debris that falls from the machines.

Extra-large plastic drip trays are essential in the industrial environment but can be used in homes and other settings too.

What Can Drip Trays Do for You?

While working around hazardous chemicals, oils and gases, there is a higher chance of leaks. In such settings, oil drip trays prevent any spill or crash and help you make your workplace as risk-free as possible.

Oil Spill Kit provides industrial drip trays in packs or private systems. You can buy whichever ticks all the boxes for you.

Why Use a Drip Tray?

- Protects workers and the environment.

- Safely stores fluid dripping from drums, containers, tanks, machinery, and equipment in the workplace.

- Protects workers and the environment from accidental spills, leaks, and drips.

- Spill trays collect liquids, preventing slips and falls caused by slippery surfaces.

- Protects the environment and soil contamination (by using large drip trays).

- They can also be used in a workshop to reduce the chances of a spill.

Various Types of Drips Trays to Choose From

For heavy machinery to operate, some form of lubricant is needed to run it properly. For instance, mobile generators leak oil and fuel; this is where fuel drip trays come in handy and catch all drips, protecting the area from hazardous chemicals and contaminants.

Depending on what you need, you can choose between the following types of drip trays in UK:

Metal Drip Trays

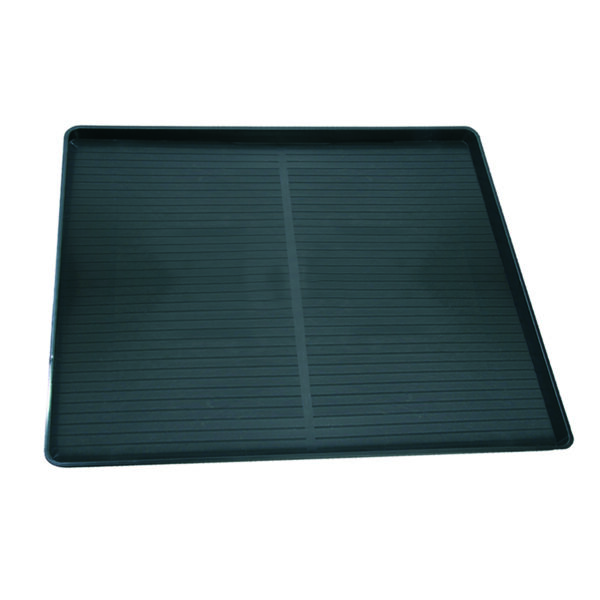

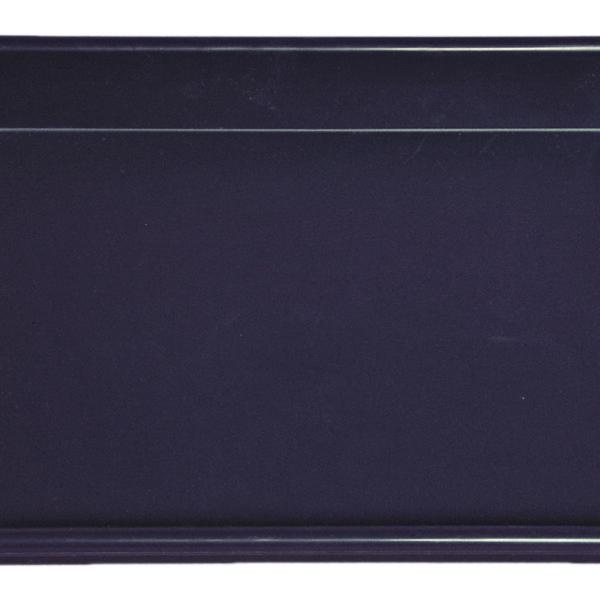

Metal drip trays are ideal for the manufacturing industry. These are ideal for managing solutions that may drip when used, and they can also be used as containment utensils for holding cans or bottles of hazardous fluids.

Polyethylene Drip Trays

Polyethylene drip trays are lightweight and available in various sizes and capacities. They are often used with absorbent pads to contain the spill quickly. These plastic oil drip trays are resistant to numerous hazardous chemicals and dangerous liquids, so they are perfect for industrial applications.

How to Choose the Perfect Drip Tray?

- Choose the correct size according to your requirement.

- Ensure it is made of a heat-resistant material; otherwise, it will melt due to the industrial tank or pot’s heat.

- Ensure the drip trays have lip-shaped edges so that you can carry the trays easily without messing up the countertops.

Benefits of Using Drip Trays

- Metal drip trays for oil can protect the surface from getting damaged by chemicals.

- Drip trays easily collect waste products, making them convenient to dispose of properly.

- They help to keep your workplace safe, clean, and secure.

Protect Natural Environment Using Drip Trays

- Industrial drip trays protect our environment, ensuring hazardous chemicals and liquids are not released into coastal waterways or roads.

- If these materials are disposed of in the water, they destroy natural habitats and wildlife.

Therefore, drip trays are highly essential as the damage otherwise caused stays around for decades.

Oil & Chemical Bunding Trays

Whether you need chemical bund trays or oil bund trays, Oil Spill Kit offers a wide range of supreme quality bunding trays in myriad shapes and sizes. Our trays act as an active barrier, preventing any leaks or spills of hazardous liquid and ensuring legal compliance with legal and safety regulations.

Key Features of Our Bunding Trays

- Suitable for repeated use

- Lightweight

- Flexible walls for easy access

- Easy to transport

- Easy assembly

- Corrosion-resistant and easy to clean

- Wash-down containment

- Infection control

- C/W shoulder bag

- Compliant legislations regulations

Shop Now!

Scroll the screen to find the best chemical bunding tray that caters to your specific needs. Also, get exciting discounts on our products!

FAQs

What is a bunding tray?

Bunding trays are large trays or storage containments, required when dealing with hazardous liquids and chemicals to prevent leaks and spills. These trays collect and preserve the liquid/chemicals to protect the workplace from threatening situations and avoid environmental contamination.

Why do I need a bunding tray?

Bunding trays help you protect from several risks i.e. accidental mixing of spills or leaks in water drains, the groundwater, or other water bodies, expensive clean-ups, workplace injuries, penalties from the local authority, adverse health conditions, and negative PR. So, to avoid these threats you need to invest in our premium bunding trays.

Do I need separate chemical bunding trays for different reactive chemicals?

Yes, always keep distinct chemical bunding trays for non-compatible and reactive chemicals to avoid any toxic/abrupt chemical reaction. It’s advisable to consult the experts at Oil Spill Kits or read material safety data sheets (MSDS)

What size/capacity should my bunding tray be?

According to UK legislation, bunds carrying hazardous substances such as oil, chemicals, or liquid waste must have a minimum capacity of 110% of the largest chemical container stored. For numerous containers, the bund must hold either 110% of the largest container’s capacity or 25% of the total combined volume of all containers.

- How do I maintain chemical bunding trays?

Bunding Integrity Test at least once in three years.

Regular inspection for cracks or damage.

Clean after spills to avoid chemical buildup.

Right positioning and stability of the tray.

Do not overload the tray over its capacity.

Home

Home  Checkout

Checkout