- Show:

Showing 1–100 of 178 results

What is Spill Containment?

Spill containment is the process of containing a leakage, spillage or any other hazardous substance within a barrier. Containing hazardous material minimises the risk of dangerous chemicals absorbing into the ground or making it to the ocean or shoreline. If not contained instantly and properly, it can direly affect human health and the environment.

The ideal spill containment depends on the storage facility, the size of the container, and the type of chemical or oil involved; for instance:

- A mobile refueler would use active containment measures to transport fuel at a non-transportation facility; in case of a spill, the team will use a spill kit to contain the fuel leak.

- A transportable generator spill containment berm will be required for a construction company that parks mobile generators at several sites.

- Moreover, many spill containment barriers exist, such as absorbent socks, booms, berms or drainage sumps.

How Does Spill Containment Work?

Spill containment refers to preventing and stopping a spill – chemical or hazardous liquids – within a drainage or barrier.

Each company has its own spill response plan stating how to stop, control and clean a potential oil, fuel or hazardous chemical spill.

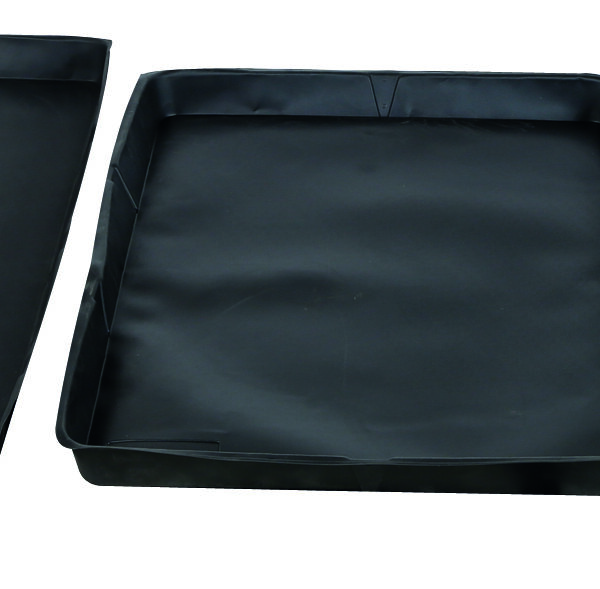

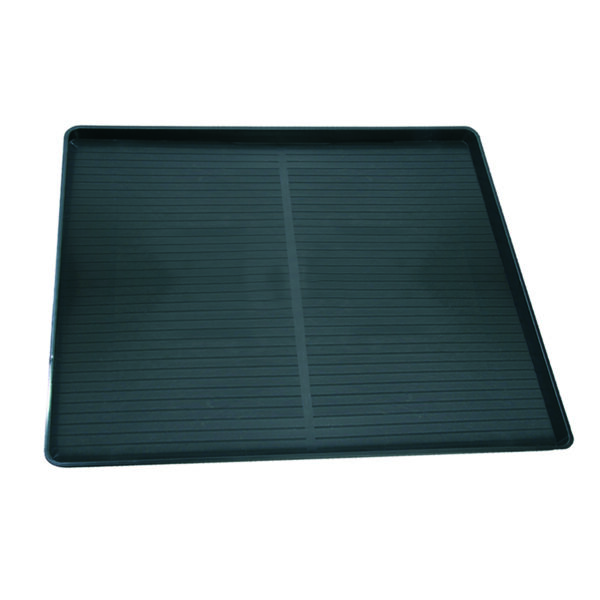

Spill containment equipment, such as dikes or berms, are used for small-scale spills, whereas a secondary containment system includes a spill deck or pallet to contain at least 55 gallons of a leak.

What Makes a Spill Containment Special?

Spill containment is necessary to safeguard people and the environment; it helps in protecting the property and surrounding areas by avoiding:

- Injury to employees.

- Risk of a potential explosion and fire due to flammable material.

- Loss of productivity.

- Loss of business.

- Building and equipment damage.

- Wastage of material and resource.

- Time and money on decontamination and cleaning procedures.

Steps for Spill Containment Systems

Spill containment systems are essential to any workplace, especially that deal with toxic and dangerous materials.

Here are some important steps for a spill containment system to function properly:

Examine Your Containers

- Regularly check and inspect your containers for any sign of damage, leaks and wear and tear.

- If any issue is noticed, fix them immediately before they lead to a spill.

Use Secondary Containment

- In case of a spill, it is necessary to have a secondary containment system as a backup.

- It would be beneficial to mitigate the oil spill impact.

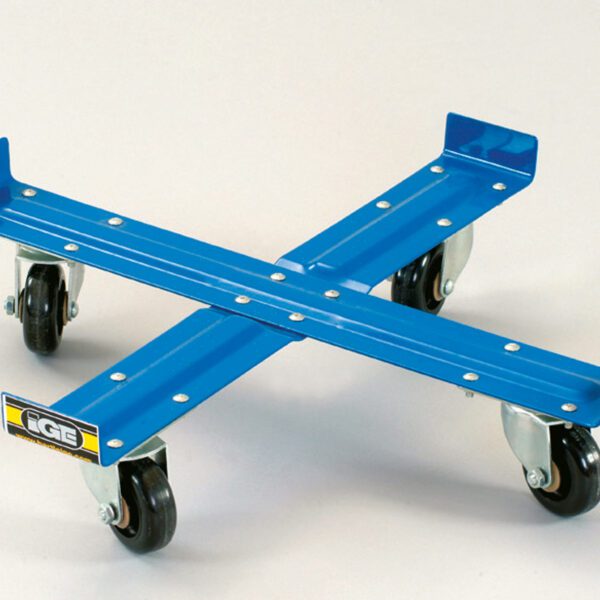

- Secondary containment system includes berms, spill pallets, etc.

- Pallets are extremely useful as they can be easily transported and moved within a workplace.

Use Spill-Prevention Equipment

- Besides a secondary containment system, having spill-prevention equipment is also essential.

- This equipment includes spill socks, adsorbents and so on.

Home

Home  Checkout

Checkout